Segmented Nozzle Fields

High convective effectiveness with locally adjustable quenching zones via activatable and deactivatable nozzle sections.

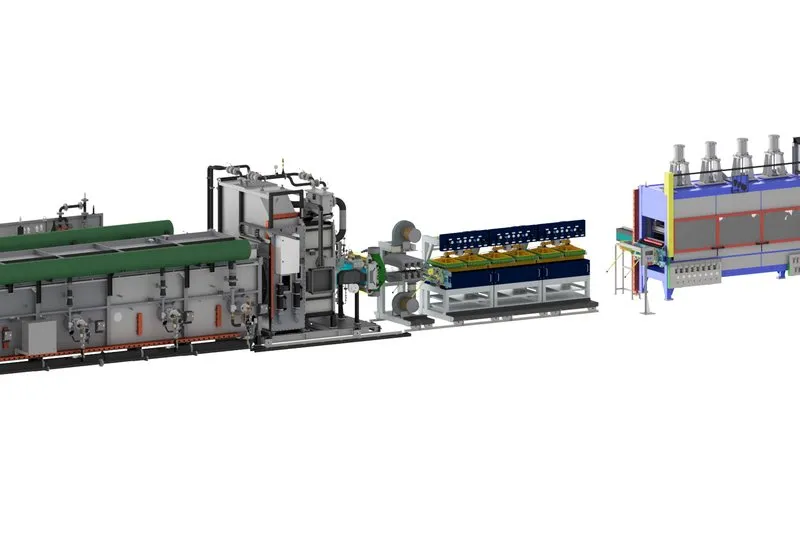

WSP supplies heat treatment and tempering lines for the hardening of carbon steel strip using hydrogen quenching based on the specially developed WSP Advanced Convection Quench (ACQ). Hydrogen as a cooling medium has been used in heat treatment for decades. The technological distinction of the WSP solution does not lie in the medium itself, but in the controlled convective impingement of the strip, replacing classical molten metal bath technologies such as lead baths.

Request Technical InformationThe WSP ACQ system is based on a specifically designed nozzle and flow geometry for intensive convective cooling of steel strip. The development objective was not a laboratory-optimized maximum cooling rate, but an industrially controllable quenching system with defined and adjustable heat transfer characteristics.

High convective effectiveness with locally adjustable quenching zones via activatable and deactivatable nozzle sections.

Suitable for single-strip and multi-strip operation with stable performance under continuous industrial conditions.

Wide adjustable range of heat transfer coefficients for adaptation to different carbon steels, strip geometries and throughput requirements.

The WSP ACQ system is in operation in several industrial applications since 2017. The systems are operated by leading strip steel producers and cover a wide range of product and throughput requirements.

Every successful project starts with an open discussion.

Get in touch with us to talk about your specific requirements and challenges – together we will find the right solution in special plant engineering.

Supplied over the past 25 years for copper and steel strip processing.

Engineered for outstanding surface quality and reliability.

Since 1989 specializing in advanced thermo-processing plants.