Material Compatibility

Process copper, brass, bronze, aluminum, and steel with the same equipment. Our furnaces handle a wide range of materials and product geometries.

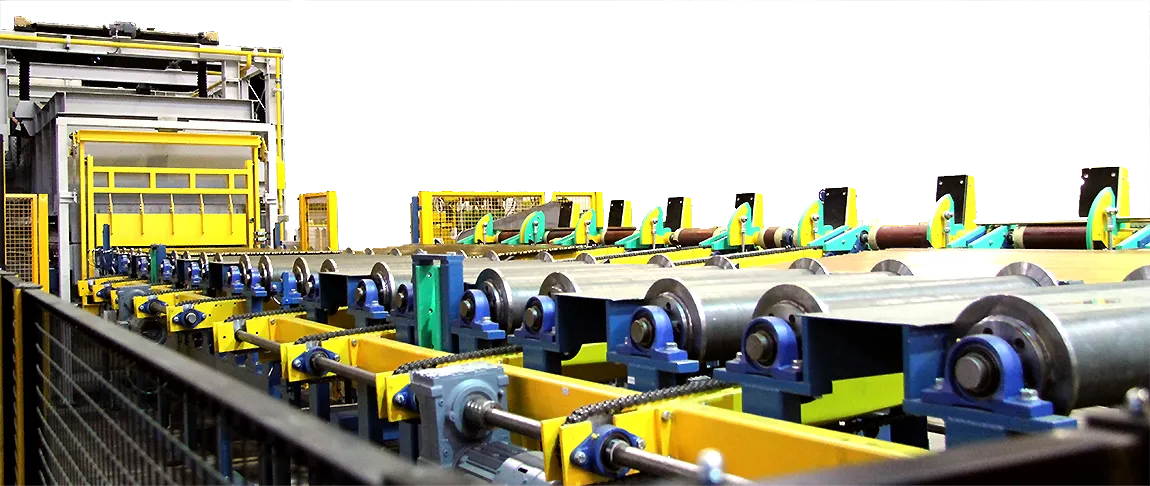

Our roller hearth furnaces enable heat treatment of bars, tubes, and profiles in both continuous and batch operation. With high temperature uniformity, low energy consumption, and powerful convection nozzle systems, these furnaces deliver rapid heating and cooling rates for optimal metallurgical results.

Request a QuoteWSP roller hearth furnaces feature modular design with pneumatic lift mechanisms for the upper shell, enabling easy maintenance and flexibility. Our powerful convection systems ensure uniform temperature distribution across the entire load.

Process copper, brass, bronze, aluminum, and steel with the same equipment. Our furnaces handle a wide range of materials and product geometries.

Operate under air or protective gas atmospheres (N₂/H₂) depending on your process requirements. Achieve bright annealing results with controlled atmospheres.

Example installation parameters for a WSP roller hearth furnace system.

Every successful project starts with an open discussion.

Get in touch with us to talk about your specific requirements and challenges – together we will find the right solution in special plant engineering.

Supplied over the past 25 years for copper and steel strip processing.

Engineered for outstanding surface quality and reliability.

Since 1989 specializing in advanced thermo-processing plants.