Specialists in Custom Furnace & Strip Line Engineering

Founded in 1989 by Prof.-Dr. Carl Kramer in Aachen, Germany, WSP has grown into a globally recognized engineering company with around 60 employees.

Our roots lie in design and process engineering, and today we combine this expertise with in-house manufacturing, assembly, and commissioning directly at our Aachen site.

We deliver custom furnaces, complete strip processing lines, revamping solutions, productivity upgrades, as well as repair and replacement projects worldwide.

1989: Foundation

Prof.-Dr. Carl Kramer establishes WSP in Aachen. Engineering and delivery of various plants.

1999: First Floatation Furnaces

Early pioneering work in strip floatation furnace technology.

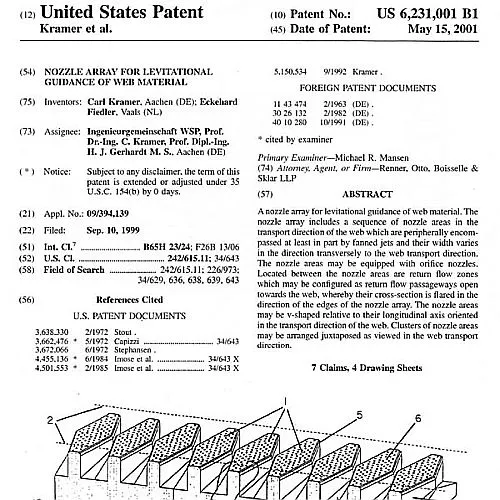

2001: Patent Innovation

Patent granted for WSP’s special floatation system.

2002–2019: Dr.-Ing. Thomas Kramer

Guides WSP as General Manager through strong growth years.

2004: Hot Gas Impellers

Start of in-house production of special impellers.

2006: New Workshop

Capacity expansion with additional production hall.

2006: Degreasing Lines

WSP extends its portfolio into cleaning & surface treatment.

2008: First Complete Strip Line

Delivery of the first turnkey strip processing line under WSP’s full responsibility.

2009: Entry into Chinese Market

WSP realizes its first projects in the rapidly growing Chinese market.

Since 2017: Dipl.-Ing. Johannes Wissen

After approx. 10 years in project management of WSP, Johannes Wissen is appointed as GM to continue WSP’s innovation-driven path.

2018: Hardening Lines

Launch of furnace systems for carbon steel heat treatment.

2022: Portfolio Expansion

Integration of a certified welding specialist company, expanding capacity for heat treatment components.

2023: Continuous Strip Line for foils

Ddelivery of a precision thin-strip processing line.

2024: Hydrogen Annealing

Fifth delivery of a WSP annealing line designed for high hydrogen concentrations for highest heating & cooling ramps.

Our Impact in Numbers – Proven Results in Thermal Process Engineering

With decades of engineering expertise and more than 200 realized projects worldwide, WSP stands for measurable improvements in productivity and plant efficiency. Our tailor-made furnace systems and line solutions deliver sustainable value for our customers in the steel and non-ferrous metals industries.

Productivity Gains

A modern WSP furnace typically increases line throughput by around 35%.

Engineering Know-how

Deep process and design expertise from continuous R&D and project execution.

Projects Completed

Custom-built furnaces, strip lines and revamping solutions delivered worldwide.

Years of Experience

Founded in 1989 – delivering thermal process technology since day one.

Throughput Increase

Typical performance boost when upgrading to a modern WSP furnace.

Employees

An experienced team combining engineering, manufacturing and project execution.

A Diverse Group of Experienced Professionals

Ready to Talk About Your Project?

Every successful project starts with an open discussion.

Get in touch with us to talk about your specific requirements and challenges – together we will find the right solution in special plant engineering.

Annealing Furnaces

Supplied over the past 25 years for copper and steel strip processing.

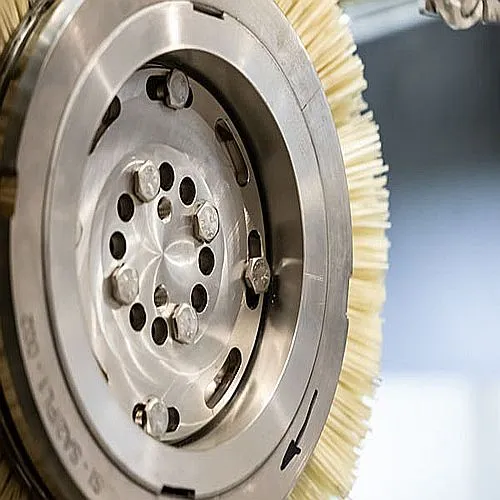

Degreasing / Brushing / Pickling Machines

Engineered for outstanding surface quality and reliability.

Years of Expertise

Since 1989 specializing in advanced thermo-processing plants.